Online technical training blog

Student Tips

We would like to thank everyone again who joined our Spring 2024 Virtual Open House.

Student Tips

On January 31st, we held an Open House session to answer your questions about our online Technical Certificate programs in electronics, electromechanics, automation, EVs, PLCs and robotics.

Student Tips

With tax season quickly approaching, it’s time to start preparing and gathering all relevant receipts and paperwork to file your taxes! Students can access and download their T2202 form from their online student account, which will account for all programs paid for during the 2023 calendar year.

Student Tips

How to Access your eCertificate when you Graduate your Program

Student Tips

An official transcript is a record of the grades you’ve earned while attending college.

Career Tips

If you come across the term, “engineering technician”, you may inadvertently make the incorrect assumption that it is just another term to describe an engineer.

Student Tips

With the holiday season quickly approaching, we wanted to update you on how the holiday break will impact our GBCTechTraining technical, tutorial, and administrative support.

Student Tips

Better Jobs Ontario (formerly Second Career) Can Help You Retrain and Re-enter the Job Market

Industry News

Unless you’ve lived under a rock, you’re likely aware that many industries, especially manufacturing, increasingly rely on automation technologies.

Student Tips

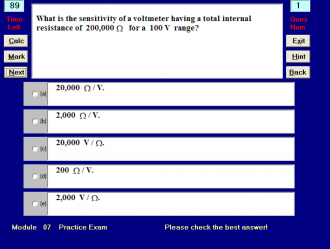

We understand that exams can be stressful for our students, so today, we're here to delve into everything related to exams and provide valuable insights.

Student Tips

Congratulations on enrolling in one of our online training programs! As you begin your training, staying organized and motivated to succeed is essential.

Student Tips

Our Facebook Group gives you the opportunity to get linked to a larger student community who share the same interests as you, a chance to network with past alumni of your program of choice and to discover new job opportunities, based on your interests.

Career Tips

The spectrum of job opportunities opening up in the Electric Vehicle Industry is very broad.

Student Tips

With the holiday season quickly approaching, we wanted to update you on how the holiday break will impact our GBCTechTraining technical, tutorial, and administrative support.

Technical Tips

In a world reliant on lightning-fast access to information, electronic controls, mobile devices, and more, it is perhaps more important than ever that manufacturers ensure that the circuits that drive their products are built efficiently and adher

Student Tips

Whether you’re an Automotive Technician, Electrician or just interested in the rapidly expanding Electric Vehicle (EV) sector you’ll want to check out our recent Webinar.

Student Tips

There are many great reasons why you should consider studying in the comfort of your own home rather than on campus. The obvious benefits – and perhaps those that come to mind the quickest – are likely to be the saving of time and money.

Career Tips

Learning to program the most powerful PLCs is an incredibly interesting and profitable skill to have, but it does come with challenges. The platforms can be complex and expensive, and the training software can be difficult to find.

Career Tips

Since COVID, online learning has emerged as a solution for practically all forms of training, including workforce development. Many community colleges are already supporting employers in strengthening their workforce by connecting with employers/organizations and offering a wide variety of work-related programs. Future jobs will need more qualifications than in the past, particularly in the areas of technology and manufacturing. This means employees must be adaptable and willing to meet these demands.

Career Tips

COVID has dramatically changed how and where we network professionally. In the past, we had many more face-to-face networking interactions through meetings, conferences, lunches etc.

Student Tips

The argument over the value of online learning has been put to bed over the last 2 years, simply based on the amazing flexibility that it provides people in their place, on their own time, and with whatever priorities th