Online PLC Technician II Training

Certificate Program & Training

The PLC Technician II program provides an advanced technical education in PLCs, giving you practical knowledge and skills you can take to work and apply right away.

Program Sidebar Menu

About the program

The PLC Technician II Certificate program provides a more advanced study of PLCs in manufacturing including Distributed Control Systems (DCS), Supervisory Control and Data Acquisition Systems (SCADA) and advanced programming languages. This program can be completed without taking the first PLC program however is more challenging to learn since it uses tag-based addressing.

The PLC Technician Certificate program is designed in a self directed format which allows our students to work on program material at a pace they feel comfortable with, at home or in their workplace, without the need to attend college on a full or part-time basis. The curriculum contains fourteen modules of theory and lab projects. Each module contains text, animations, mini audio lectures, illustrations, review questions, pre-built lab projects and practice exams that engage and train with the concepts common to all robots.

Highlights

Simulation software

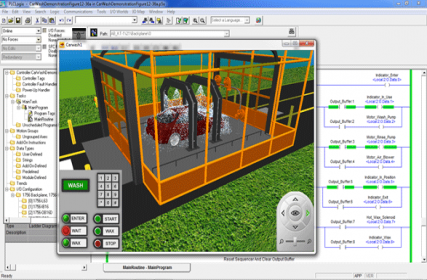

The simulation software, PLCLogix 5000 is designed to emulate the Studio 5000/RSLogix 5000 (Rockwell/Allen Bradley) series of PLCs. This simulation software includes approximately 250 pre-built lab projects; including 50 lab projects presented in 10 “real world” 3D PLC application environments. One of the main advantages of using PLCLogix is that it provides much-needed “hands on” experience in the operation of RSLogix and ControlLogix software and hardware.

PLCLogix 5000 Simulator

PLCLogix 5000 allows you to create ladder logic programs, see the program’s operation using a simulator and control the operation of the program from within this interactive environment. It replaces the PLC ladder rung editor and all the electrical components that have, until now, been required to learn PLC programming and operation.

The PLCLogix 5000 simulator incorporates a “Tag” based addressing system employed by 5000 series Control Logix controllers. The Tag Editor and Tag monitor interfaces allow for program variables, instruction elements as well as physical I/O to be not only edited and monitored as required by real world applications but also to be grouped and organized as desired, using tags and aliases. The integration of the ladder logic programs with the 3DWorlds provides a unique opportunity for programming in real-time and observing the operation of complex control devices and systems. PLCLogix 5000 features 10 “real world” 3D PLC application environments including batch processing, elevators, traffic lights, car washes, etc. These interactive animations graphically simulate process control operations in the following applications: Batch Mixing, Bottling Line, Dual-Compressor, Elevator, Moving Car Wash, Silo, Single-Compressor, Stationary Car Wash, Traffic Lights and Warehouse Door.

PLC Technician II

Over 250 pre-built lab projects allow students to develop their programming skills to write, test and de-bug PLC programs using an interactive I/O interface and the eleven 3D worlds.

PLC Technician II

Using PLCLogix 5000, the student is able to gain much-needed programming practice by creating and running their own ladder logic programs using tag-based memory. PLCLogix 5000 functionality includes a graphical controller organizer and a point-and-click method of configuring various I/O.

PLC Technician II shares a common core of seven modules with the PLC Technician program, including I/O System, programming terminals and peripherals, installation & maintenance of PLCs, timers, counters, sequencers, process control.

Program Costs

George Brown College offers you a number of easy registration options, to make it convenient and affordable for you to register in the Electronics Technician Certificate. You can registration for the program in full, or if you prefer, you can pay module-by-module with our pay-as-you-learn option or just purchase the curriculum material on its own. Our pay-as-you-learn option gives you the ability to begin the program after paying a portion of the cost, and as you work your way through the program you will pay for your next module as you access it. If you are on a budget, this can be a great way to get started on or continue your education without a huge up-front investment.

Additional Online Program Resources

To further enhance the program and provide supplemental learning the Online Student Resource Center offers additional resources including alternative study content, examples, exercises, tutorial videos, student tutorial forums and the online exam center.